Tobacco

counterfeiting

Anti-counterfeiting solutions for tobacco products

The tobacco industry is not limited to just tobacco-based products. A huge range of accessories and materials provide an additional revenue stream for many tobacco companies. With increasing public awareness of the negative health effects of smoking, the tobacco industry is being forced to diversify and explore new markets. Simultaneously, the tobacco industry has also been facing an ever-increasing problem with counterfeit and contraband cigarettes. Approximately 450 billion counterfeit cigarettes are sold around the world annually, causing huge losses in revenue and taxes. It is important to note that regulatory obligations have been put in place all around the globe by international and national bodies to stop this. The regulations range from reduction of tobacco product consumption to the protection of tobacco products against counterfeiting.

The legal age of tobacco product consumption depends on which country you look at. Most countries allow people to buy tobacco at the age of 16. In some, it is illegal for them to consume it before the age of 18 or 21. Additionally, the sale of these products is forbidden in some countries such as Turkmenistan.

WHAT IS TOBACCO?

The tobacco industry offers a wide range of products. Tobacco is usually processed into cigarettes. However, there are other products which could be consumed both orally or nasally, by chewing, sucking or sniffing. These include:

- Cigars

- Cigarillos

- E-cigarette of all kinds

- Loose tobacco

- E-liquid

- Snuff

- Snus

How Tobacco is made

Tobacco is grown and harvested in more than 120 countries including Switzerland, although in a low quantity for Switzerland. China, India, and Brazil are the largest producers in the world. Many different types of tobacco exist, offering different tasting notes and flavors. The most popular types of tobacco are:

Brown – pungent

British – more aromatic and marked

American – toasted, spicy with special notes

Often a blend of the three is used in tobacco products, giving it a rich and distinguished flavor. A cigarette is usually made of 20 to 40 different leaves.

In the tobacco industry, the following steps are generally executed to create tobacco products such as cigars. First and foremost, the leaves must be cultivated. Per hectare, it is possible to plant around 35’000 to 40’00 plants. The leaves on the bottom of the plant are quick to mature. Therefore, the picking is done from the bottom to the top at different intervals. Due to the difference in maturation, the harvest takes between 6 and 8 weeks. The quality of the leaf depends on the stage of the plant. The leaves from the top have more concentrated levels of nicotine. The leaves are then suspended and dried in sheds.

There are 4 aspects to drying the tobacco.

- Drying in the open air (between 3 to 30 days) (Brown tobacco)

- Sun-cured

- Flue-cured (Blond tobacco)

- Flue-cured

The leaves lose up to 80% of their mass in the drying stage. During this step, the color of the product changes from green to brown and the aroma of the tobacco begins to reveal itself. Drying is followed by different types of fermentation, lasting 3 to 4 months.

- Natural fermentation (most used for cigars)

- Room fermentation

- Fermentation in machine

During the fermentation process, the temperature does not exceed 70° degrees. The leaves are regularly turned. Subsequently, this raw material is treated and transformed in a primary processing stage which includes mixing different tobaccos from different areas and quality. They also adjust the nicotine dosages and sometimes add new flavors. Finally, the mixture is stirred and then beaten in blowers. The manufacturer will receive the merchandise and create the finished products. It will be packed up and moved into the distribution channel which sells the tobacco in their boxes.

Tobacco counterfeiting consequences

There are many dangers from smoking fake tobacco products. In addition to being dangerous for the consumer health, the counterfeits may have a serious impact on the brand reputation. In some industries, the packaging is reused and refilled. In most instances, the fragile tobacco packaging is generally not resistant enough to be reused. Therefore, counterfeiters try to reproduce them identically including the visible security features. On the top of that, resellers sell illicit merchandise without being taxed, costing governments and taxpayers billions.

GOVERNMENT AND LEGISLATIVE REQUIREMENTS

Several measures have been put in place by the European Union and national governments to legislate against selling tobacco products. These include:

- Track and trace and security features to fight against fraudulent attacks

- Regulation of packaging and ingredients

- Increased tax measures

- Advertisement restrictions

Primarily, these policies aim to decrease the number of consumers, notably among young people, by increasing the price of the tobacco products using governmental tax. At the same time, some countries impose the addition of shocking images to the front and back of packaging, the images showing the health-related risks of smoking. The images should make the consumer aware of the fact that smoking is not healthy and hence reduce consumption of tobacco products.

On top of this government taxes now take almost 50% of the final price plus the VAT and in some cases a small percentage is used for health insurances.

Today, we know the importance of marketing and promotion. Tobacco companies, who are used to allocating a huge amount of money to advertising, are now also forced to put anti-counterfeiting technologies in place in response to the proliferation of counterfeiting.

SECURITY FEATURES REQUIRED

One of the four control measures put in place in Europe is to carry an invisible or covert security feature and a track and trace system to fight tobacco counterfeiting. The authentication technology is required to be printed and irremovable. Some fiscal instruments such as tax stamps or national identification marks could also be used as a security feature as long as they fulfil the technical standards imposed by the legislation. Obviously, the implementation of these solutions should not have a negative impact on the packaging regulations.

To know more about the official directive of the European parliament and of the council click here.

Counterfeit protection solutions

There are different ways to protect the tobacco industry against counterfeiting.

These approaches are adapted for different user groups and problems.

OVERT AUTHENTICATION SOLUTIONS

Visible security features are, as the name suggests, visible by humans and include QR codes, holograms, optical variable inks, watermarks, and security threads. These are the most frequently used solutions in the tobacco domain to protect a product from fraudulent attacks. At first thought, it may seem a good way to ensure a product and brand authenticity to the end-user. However, end-users often cannot determine if the visible security feature itself is authentic. Furthermore, it is often simple for counterfeiters to reproduce visible security features. It should also be noted that it might be a real disadvantage for the brand if they want to remove the overt solution as it may trouble the end-users. Even if the brand tried to inform the end user that they will be removing the security feature, buyers may persist in thinking that they might be buying a counterfeit product.

COVERT AUTHENTICATION SOLUTIONS

As indicated by its name, the covert security features are invisible to the naked eye. Examples are invisible inks, fluorescent color trackers, or special chemical tracers. These technologies generally require a special reading device and are therefore in general used for internal use by, for example, brand owners, law enforcement, governments and distributors to verify the authenticity of the products. The invisible solution enhances the security level of your product. It cannot be as easily duplicated as an overt technology.

TRACK AND TRACE

Track and Trace is used to track a product at every step from its production through distribution along the supply chain, to the end-user by adding a UID (unique identifier) such as bar code, scratch-off, serial number. Track means the current and the past locations of the products. Trace informs about the origin of the product and the various stages his has gone through during its lifetime. Nevertheless, it is important to note that Track and Trace does not bring any protection level against counterfeiting.

AUTHENTICATION SOLUTIONS PROPOSED BY ALPVISION

All anti-counterfeiting solutions provided by AlpVision for tobacco products are covert, which means there is no visual modification on the product. Depending on the product, one of three authentication solutions could be implemented on the different type of tobacco products. All three solutions proposed by AlpVision use a smartphone with a dedicated application. It is compatible with both iOS and Android.

CRYPTOGLYPH

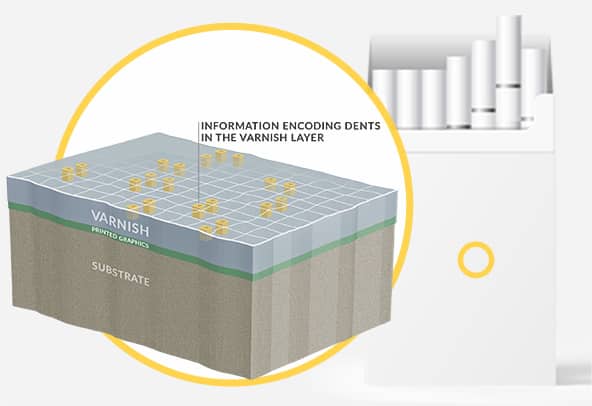

The Cryptoglyph technology is an invisible technology suited for printed products such as packaging, labels, and blisters. The principle is simple and does not require any aesthetic modification of the packaging artwork. During the standard printing process, Cryptoglyph adds thousands of micro holes in the varnish layer or in the solid color area of the printed product. No special inks or varnish are needed, and this solution can be applied with your current printers. To find out more about this solution click here.

FINGERPRINT

The Fingerprint is designed for physical products such as e-cigarette, e-liquid, snuff, or snus packaging. The moulds used to produce these items create the same microstructure on each and every piece for the same cavity. Thanks to a reference image of the product per cavity, our solution can detect the micro “defects” and authenticate the product. Absolutely nothing is added or modified on the product. Discover all the technical aspects by clicking here.

SECURED QR CODE

The secured QR code is like the Cryptoglyph.

By adding thousands of micro holes in the black areas of the QR code during your current printing process it is possible to secure a standard QR code without any visible modification. The additional invisible security layer protects the QR code against copying. Discover more about the secured QR code by clicking here.

STATISTICS AND REPORTING –

BRAND MONITORING SYSTEM

For all of AlpVision’s technologies the detections made are stored in a web interface called the Brand Monitoring System. This platform allows the brand owner to have a real-time and insightful look at quality control and counterfeit activities. It is totally customizable and provides data such as the location, the time and the day, the result of the authentication, the operator… Moreover, even if some detections have been made offline, the result will be stored on the phone and will be automatically uploaded as soon as the operator is once again online. Discover more about our BMS here.

Counterfeit Products Market

PHARMACEUTICALS

TOBACCO

GOVERNMENT

PRECIOUS METALS

WINE & SPIRITS

AUTO LUBRICANTS

OTHER INDUSTRIES

Our digital invisible technologies for product authentication and counterfeit protection can be applied to a broad range of branded products across a multitude of industries, including household appliances, electromechanical parts (e.g., circuit breakers), agrochemicals (e.g., pesticides), cosmetics, oil & gas (e.g., lubricants), consumer goods, food & beverage and more.

Would you like to see how this technology can be applied to your product?

Contact us!