The future of plastic recycling is in accurate sorting to allow circular plastic economy of such materials as recycled PET, PPT, PP. Plastic is a very useful material, which is hard to replace in many applications. However, the way we handle it and its effect on the environment needs to be changed.

Sustainable plastic recycling is needed to reduce the impact of environmental plastic pollution. Accurate plastic sorting to separate different types of resins, such as polyethylene terephthalate (PET) or high-density polyethylene (HDPE) for different applications (food-grade vs. non-food grade) and effective recycling are necessary steps to be taken towards sustainable plastic use.

For this reason, many projects have been tried by different regions, to move away from a linear plastic economy, where plastic material goes in one direction only, from product to ever accumulating waste. An alternative to this is a circular plastic economy, in which plastic circulates in a closed cycle: from a product to recycling and recovery, allowing the material to be re-used for new products.

There is increasing pressure from customers and regulators to increase plastic recycling. However, this is a complex process requiring cooperation across different industries, and which includes brand owners and recyclers. This is a real challenge for the plastic industry, a contemporary Holy Grail, as it was called in one of the European Union’s initiatives to implement improved sorting technologies.

How plastic is recycled today?

According to a recent McKinsey report recyclers struggle with:

- lack of product standardization

- volatile customer demand

- inefficient sortation processes

Currently, the most often recycled plastic resins include polyethylene terephthalate (PET), polypropylene (PP), polyethylene (PE), polyamide (PA), acrylonitrile butadiene styrene (ABS), polycarbonate (PC), polyvinyl chloride (PVC) and polystyrene (PS).

US-based Environmental Protection agency reports that only 8.7% of plastic was recycled in US in 2018. The rest is handled in a much less environmentally friendly way, mainly by incineration and landfilling.

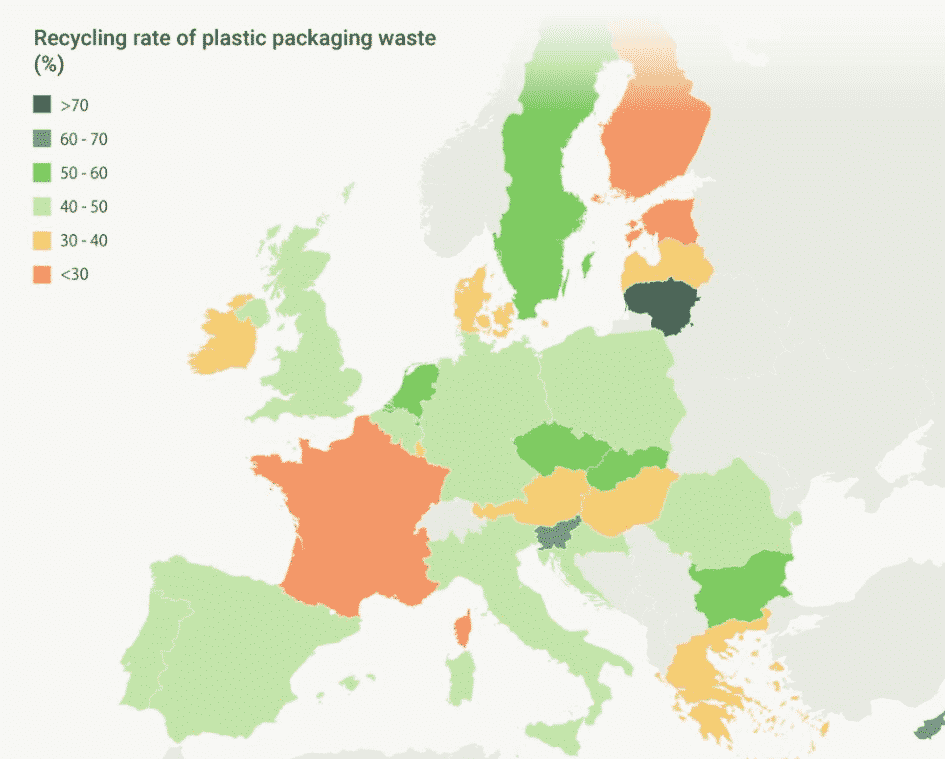

Eurostat reports that approximately 40% of plastic is recycled in EU. According to the data from European Parliament, Lithuania is the European leader in the percentage of plastic recycled (over70%), while most of the European countries recycle less than half of their plastic waste (picture below). This also causes significant CO2 production, as one of the main methods for handling the plastic waste is incineration.

Brand owners put efforts in improving the recyclability of the plastic material they use, this includes tagging the material to improve sorting process.

What is a ‘dream’ technology to improve sorting of a wide variety of plastic products?

According to the Holy Grail report key requirements for a technology to improve plastic sorting include:

- Non-permanent marking to avoid cross-contamination in next cycle, (e.g. a chemical tag will stay in the plastic substance forever and accumulate during the cycles)

- No issue for food safety

- Distinguish food grade non-food packaging

- Sort out easily compostable packaging

- Sort all types of PET bottles

- Facilitate new material introduction

- Encode multi-layer material components

What AlpVision is proposing?

AlpVision is a world leader in invisible marking technologies. Our technologies to identify products do not require any additional chemicals. Therefore, they are suitable for any type of packaging, including food-grade packages. This would also be perfect for repeated usage cycles, as no additives would accumulate during reuse of the same material.

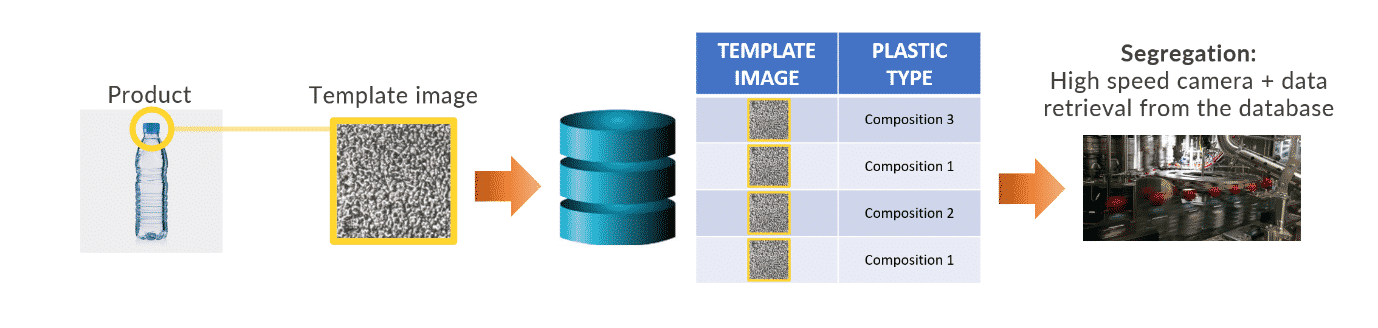

Fingerprint® technology allows image-based recognition of plastic components, without any surface pretreatment. The analysis is based on the intrinsic microstructure of the matte finishing on plastic. This allows unique characterization of each product or product batches by just taking a reference picture.

This reference picture can be used for authentication, product tracking or potentially, for sorting of different types of plastic products using a high-speed camera.

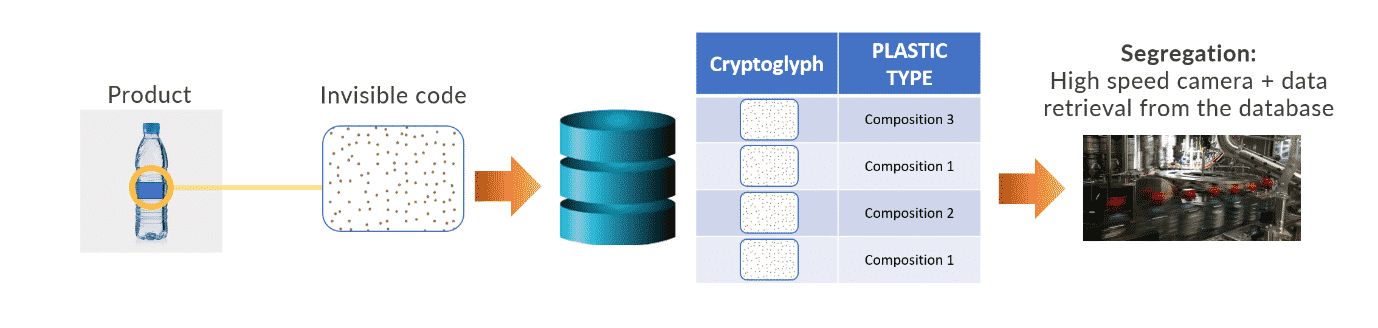

Cryptoglyph® technology allows image-based recognition of a wide variety of packaging materials, including plastic. Here, we print small dots on the package. Dots are invisible to the naked eye but can be detected with our patented algorithms, just by taking a picture.

Some other ideas we find interesting: near-infrared fingerprint.

Near infrared is currently used in some recycling facilities, especially in US. It is based on the fact, that different plastic materials reflect red light slightly differently. The light emitted on a plastic element will bounce back in a unique, detectable way. From this, we obtain a reflectance curve, which is a unique ‘NIR fingerprint’ of the material. However, this method has some significant limitations:

- it is difficult to apply on black plastic, which reflects infra-red light poorly

- it does not allow collecting information about food-grade non-food grade materials.

The real challenge is to select multilayer material from homogenous ones, e.g. PET bottles with a protection barrier from pure PET bottles.

Improved NIR-based sorting equipment are being developed rapidly, and we believe that applying advanced AI-based methods to analyze reflectance curves can improve the sorting accuracy.

In any case, improvements in plastic recycling will require cooperation between brand owners, recycling facilities and technology providers.

Interested to know more about our expertise and technologies?

Get in touch with our team!